Without NASA’s expertise, Musk’s rockets would be tubes on a launchpad.

U.S. taxpayers spent nearly $25 billion on SpaceX from 2002 through mid-2025. #NASA’s decades of proven mission success, rigorous safety culture, and extensive technical expertise surpass those of SpaceX’s achievements. Elon Musk’s reckless leadership and habit of prioritizing speed over safety have led to repeated failures, forcing NASA to bear additional costs and risks while draining critical talent.

NASA built its reputation on meticulous engineering, having launched humans to the Moon, maintained the Space Shuttle for 30 years, and operated complex interplanetary probes. The Department of Defense and U.S. intelligence agencies shifted billions of dollars to SpaceX under NSSL Phases 1–3 and covert satellite programs. State and local governments in Texas, Florida, and California showered SpaceX with grants, tax breaks, and infrastructure improvements. Veteran NASA engineers and safety specialists abandoned civil-service roles for the allure of Musk’s high-pressure startup, lured by higher pay and stock options.

NASA committed $278 million in 2006 under COTS. After Falcon 1 finally reached orbit in 2008, NASA paid $1.6 billion for CRS-1, which swelled to $3–4 billion under CRS-2. Commercial Crew poured $4–5 billion into developing Crew Dragon. Artemis HLS commands accounted for $4.05 billion. Scientific-launch contracts exceeded $1 billion. The DoD publicly logged $7.6 billion in launch-service awards and likely spent an additional $2–3 billion on classified contracts. State and local agencies resembled complicit enablers, offering $20 million in subsidies. Total nominal funding reached about $25 billion.

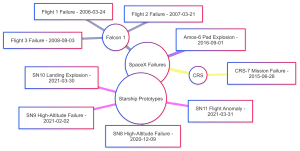

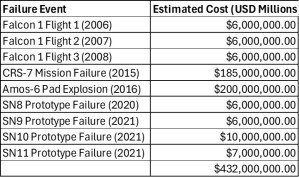

NASA’s painstaking design, rigorous testing, and layered oversight minimized failures. In sharp contrast, SpaceX recorded at least a dozen major launch disasters during its first decade: three Falcon 1 failures before 2008, a CRS-7 breakup in 2015, the Amos-6 pad explosion in 2016, and half a dozen Starship prototype blowups in 2020–2021. Each mishap forced NASA and DoD to scramble for backup capacity, negotiate emergency contracts, and shoulder extra costs. Musk’s “fail-fast” ethos morphed into a “fail-often” reality, bastardizing safety margins and straining partner relationships. Meanwhile, NASA hemorrhaged engineers whose lost expertise cannot be replaced quickly. Dependence on a single unstable vendor opened gaping vulnerabilities: any serious SpaceX fault could ground Artemis, stall national security launches, and weaken the U.S. strategic posture.

Musk’s ambition to land humans on the Moon and later Mars hinges on Starship passing demanding orbital tests. Geopolitical competition with China and Russia requires a reliable launch capacity that SpaceX has yet to demonstrate under all conditions. The ongoing conflict in Ukraine has heightened Starlink’s strategic utility, prompting the DoD to fund the service through 2027 despite its unproven performance under sustained military use. NASA confronts budget constraints and must adhere to aggressive Artemis schedules while losing seasoned personnel to Elon Musk’s revolving door. Pressures to slash launch costs collided with NASA’s struggle to maintain rigorous review boards as key staff decamped.

NASA’s historical track record speaks for itself: Voyager probes soared to interstellar space on first attempts; Mars rovers landed precisely with near-perfect execution; Hubble repair missions overcame unanticipated challenges. SpaceX’s track record looks messier. After CRS-7 failed, NASA had to buy additional Soyuz seats and delay cargo flows. Amos-6 destroyed a $200 million communications satellite and wrecked a launchpad. Starship’s string of prototype implosions wasted billions and postponed Artemis HLS timelines. A hidden toll arose from a morale collapse within NASA, as managers feared losing further experts. NASA ceded pad 39A to SpaceX while enduring pad accidents that cost priceless heritage infrastructure. Each SpaceX failure resulted in the realignment of government schedules, higher insurance costs, and frayed trust among international partners.

SpaceX sits on a $10 billion-plus backlog: Artemis HLS, NSSL Phase 3, Crew and Cargo extensions, and Dragon XL missions. Musk’s aggressive timelines risk spectacular failure—one Starship breach during a high-profile Artemis test could trigger congressional backlash, stall lunar return plans, and undermine U.S. deterrence. ULA and Blue Origin lack SpaceX’s vertical integration and pace but maintain stricter safety cultures. Starship’s next accident could tip NASA toward diversifying suppliers or resurrecting legacy heavy-lift designs at higher cost. NASA’s depleted technical ranks struggle to critique SpaceX’s fast-tracking of unvetted innovations. Musk’s penchant for mid-night Twitter pronouncements, misleading cost narratives, and belittling critics eroded congressional trust. Without course correction, NASA will lack the internal depth to oversee next-generation systems or pivot if SpaceX self-destructs under its ambition. Congress and NASA leadership must weigh short-term savings against the long-term strategic risk of a single-point dependency on an erratic CEO whose decisions often prioritize publicity over prudence.

NASA injected $15 billion into SpaceX and the DoD another $10 billion, crowning Musk the nation’s top government contractor while hollowing out NASA’s talent pipeline. Engineers who once led Shuttle avionics, dive-tested heat shields, and fine-tuned ISS rendezvous now toil under Musk’s frantic pace. That exodus eroded NASA’s bench strength just as Arctic-class deep-space missions demand seasoned systems engineers. Civil-service vacancies persist, forcing reliance on contractors lacking NASA-caliber rigor. Institutional memory from Challenger’s O-ring investigations and Columbia’s foam-strike forensics risks vanishing as fewer civil servants remain who recall how to catch subtle failure modes. NASA now depends on a private firm whose leader cavalierly dismisses failures as “learning experiences” while social media fans cheer every rocket test … unless it blows up spectacularly.

SpaceX’s government backlog and excited private demand propel rapid growth. A flawless Starship debut could cement Musk’s monopolistic position and justify Congress funneling even more funds his way. However, a catastrophic failure during a crewed Artemis mission would reverberate across NASA, the Department of Defense (DoD), and global partners, exposing a deeper fragility resulting from over-reliance on Musk’s unpredictable leadership. NASA must rebuild in-house expertise, invest in alternative heavy-lift systems—perhaps reviving concepts from canceled programs—and insist on onerous safety milestones before awarding more contracts to SpaceX. Without bold action, NASA risks losing its role as mission architect, ceding strategic sovereignty to one man’s ego and Twitter feed.

Apollo’s successful

NASA has amassed unparalleled expertise through decades of exploration, deep‐space missions, and human spaceflight programs. Early efforts under Mercury and Gemini tested life support, propulsion, and rendezvous techniques, laying a solid foundation for Apollo’s triumph in landing humans on the Moon. Engineers refined launch vehicles, navigation systems, and safety protocols across countless missions. Successive programs—Skylab, Space Shuttle, and the International Space Station—expanded knowledge of orbital operations, in‐orbit repairs, and astronaut health. Mars rovers, Voyager probes, Hubble servicing, and Juno’s Jupiter exploration demonstrate NASA’s ability to design complex spacecraft, forecast risks, and solve unforeseen challenges in harsh environments. A large civil‐service workforce with deep institutional memory supports rigorous peer review and redundant checks at every stage of design, testing, and launch preparation. That collective experience has produced reliable spacecraft that have flown hundreds of missions with a strong safety record.

Decades of incremental development at NASA produced mature, thoroughly vetted hardware. Launch Complex 39, built for Saturn V, evolved into a multiuser pad for Shuttle and Artemis test flights. Mission control centers refined real‐time anomaly response with redundant communication links and highly trained flight directors. Layered testing phases—from component validation in clean rooms to full‐duration engine firings at test stands—caught flaws before flight. Engineers refused to accept unproven shortcuts, enforcing strict criteria for life‐support systems, heat shields, and software validation. Astronaut crews trained in high‐fidelity simulators to rehearse dozens of emergency scenarios. Safety boards and independent panels reviewed every anomaly, then required corrective measures before resuming operations. That exacting process helped prevent catastrophic failures over long program lifespans, yielding a legacy of dependable missions across hundreds of launches.

SpaceX’s record highlights frequent errors and safety lapses, especially during rapid development phases. Early Falcon 1 flights failed three times before reaching orbit in 2008. In 2015, a Falcon 9 rocket exploded during a routine resupply mission to the ISS (CRS‐7), destroying critical cargo and jeopardizing station operations. Later that year, a Falcon 9 carrying the Amos-6 satellite erupted on the pad during a static fire test, damaging infrastructure and delaying commercial launches. Starship prototypes suffered multiple high‐altitude failures, with several vehicles blowing up during descent tests in 2020–2021. Crew Dragon experienced anomalies during an uncrewed in-flight abort test, forcing engineers to isolate a coolant leak and delay astronaut flights. While SpaceX often recovers quickly, its habit of testing live hardware without mature ground validation creates avoidable risks. Those incidents caused expensive setbacks, eroded confidence among partners, and raised concerns about overlooked design flaws in pressurized vessels and avionics.

Comparing institutional strength reveals clear disparities. NASA’s engineering culture anchors decisions in peer-reviewed data, red-teaming exercises, and conservative timelines. Teams assemble survivors’ lessons from Challenger and Columbia accidents, ensuring that every system satisfies multiple, independent reviews. By contrast, SpaceX relies on a “fail fast” strategy that accepts destruction of prototypes as part of learning. That philosophy accelerates iteration but sacrifices reliability, especially when moving from test vehicles to operational missions. SpaceX’s rapid cadence places pressure on supply chains and quality control. NASA programs, with lower launch rates and fixed budgets, emphasize exhaustive validation over speed. Talent migration to SpaceX deprives NASA of seasoned experts who know how to anticipate subtle failure modes. Without abundant, experienced civil servants guiding next‐generation programs, NASA struggles to maintain its well‐practiced workflows and risk management rigor.

Safety records reinforce that contrast. NASA logged few catastrophic failures once robust quality procedures matured—nearly all Shuttle flights proceeded without major incident after 1988, and ISS resupply ships from SpaceX became reliable only after early mishaps. NASA’s robotic missions, such as Curiosity and Perseverance rovers, succeeded on first attempts thanks to exhaustive simulations and hazard analysis. SpaceX regained ground by adapting designs quickly but repeated anomalies raise questions about systemic robustness. A major Starship failure during a critical Artemis campaign could delay lunar landings and jeopardize national prestige. Overreliance on a private firm with a track record of explosive tests and pad accidents risks mission continuity if SpaceX encounters software errors or propulsion defects. NASA’s decades of patience and process refinement produce steady gains, whereas SpaceX’s high‐speed approach often courts dangerous surprises.

Institutional depth, rigorous safety protocols, and decades of mission success give NASA capabilities that no private firm can match today. SpaceX’s achievements in reducing costs and pioneering reusable rockets represent a valuable complement—but not a replacement—for NASA’s institutional knowledge, extensive safety culture, and hard-earned track record. Preserving NASA’s skilled workforce and ensuring robust oversight of SpaceX projects remain essential. Otherwise, rapid commercialization could overshadow mission assurance, leaving critical national space objectives vulnerable to preventable failures.

Musk’s public image thrives on slick marketing rather than genuine rocket science. NASA engineers built the foundation—designing engines, mastering life-support systems, and perfecting launch procedures over decades. SpaceX might have grabbed headlines, but every milestone relied on expertise that NASA paid for, trained, and tested to death. Fans credit Musk’s “genius,” yet NASA’s veterans handled safety boards, battered down failures, and handed SpaceX a playbook. Without NASA’s know-how, Musk’s rockets would still be metal tubes on a pad.

You must be logged in to post a comment.